Services

From in house and site repairs to project support for installation, commissioning and annual maintenance, our Service Department, of highly qualified and experienced technicians, are able to cover every aspect of your valve and automation service needs.

Power Mechanical Services

Our service repair option is ideally suited to customers who have highly critical actuation and controls needs that should they fail can cause significant impact or possible shutdown of operations.

We stock a number of dedicated actuation and control serviced products for customers. In the event of a site failure the serviced repair unit can be instantly dispatched and substituted by site or by our service teams ensuring that downtime is at a minimum. The failed unit is returned to our works and repaired or re-furbished, tested and booked back into stock.

Planned Service Schedule

We offer customers on site and in-house service agreements for valves, actuators and controls supporting the maintenance requirements of the critical equipment installed and ensuring that unexpected failures are minimised.

We adopt a collaborative service agreement process where a detailed asset condition assessment is carried out, full reporting and recommendations are produced to give customers a clear insight into the condition of equipment and maintenance priorities to ensure operational consistency.

Contact our Service Department for a bespoke and innovative approach to your maintenance needs.

POWER MECHANICAL

INSTALLATION & COMMISSIONING

As a service lead company our strength and USP has always been in our ability to, not only, supply high integrity equipment but to follow it to site, install and commission it as a turn-key service that guarantees our customers’ expectations and needs are met and exceeded.

Favoured by many of the UK gas operators and their main works contractors, as well as some of the leading oil and gas producers, we are pleased to have been involved in some of the leading capital projects both onshore and offshore.

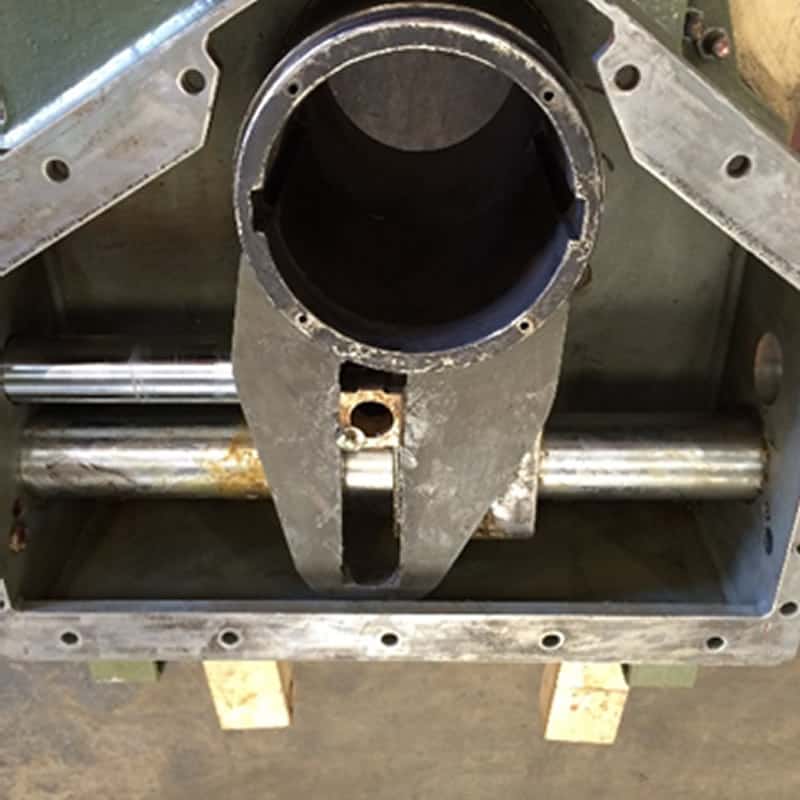

RETROFITTING SERVICES

Upgrading, replacing and modernisation of existing oil and gas capital infrastructure has been a key service product for Power Mechanical for many years.

We offer full site surveys to determine the required scope, provide technical recommendations, actuator sizing and dimensional verification of existing valves to determine mounting requirements.

As a result of our long-standing relationships with many of the worlds leading valve manufacturers, we are often able to recover unavailable historical data allowing us to provide a full retrofit service. Once the data is recovered and the technical scope is defined, we take care of the rest from the detailed design, removal of the existing equipment, installation, commissioning, validation and certification of the new equipment.

Please contact our Service Team specialists for case studies and recommendations.

CONDITION ASSESSMENT

As much of our gas transmission and oil and gas production facilities continue to operate effectively way past their intended design life, understanding the condition of safety critical equipment is becoming increasingly more and more important.

We offer our end user clients a tailored Condition Assessment Service for high integrity valve actuation and controls. Onshore of offshore our experienced valve, actuation and controls technicians can carry out a detailed survey highlighting equipment condition with a detailed report coupled with recommendations to ensure that Operations are able to manage maintenance effectively before a failure or breakdown occurs.

Condition assessment surveys also provide the opportunity to update plant inventory as well as assess potential spares needs.

ESD TESTING

A service developed more than 10 years ago in partnership with Shell and still carried out by our Service Department annually, ESD valve testing has proven to be a reliable tool when managing regulatory requirements for Emergency Shut Down valves.

Verification of the operation of ESD SIL3 and SIL2 valves is a mandatory requirement, however where ESD valves are installed on the main arteries of production and process facilities, a full or partial plant shut down is required to prove these valves.

We provide on-site testing facilities to prove and document operational suitability for Emergency Shut Down Valves without the need of production interruption or plant shut down.

ON-SITE VALVE FLUSHING & INJECTION SERVICES

Reliable valve operation, as with most things, is down to good maintenance. Valve operation performance and leakage rates can be greatly improved with regular flushing and injection.

Our Service Team specialise in providing high pressure flushing and sealant/lubrication services to pipeline valves whether they a buried or above ground. Our experience and long-standing relationships with the world’s leading valve manufactures ensures that our Service Technicians have detailed knowledge of the valves they are working on and the flushing and sealant/lubricant products are those recommended by the OEM.

Weather you have a one-off requirement or are looking for annual valve support, our Service Department can provide you with national support.

INSTRUMENTATION VALVE REPAIR

Instrumentation valves are often critical to the operation of oil and& gas facilities, in particular for wellhead controls and sub-sea control manifolds.

Having worked with some of the leading instrument valve manufacturers providing service support, new product build and new product testing, our experience and ability to provide a fast turnaround repair service has made us the support partner of choice for many end users.

Supporting the major operators in the Southern Sector of the North Sea for emergency valve repair, spares and new equipment from our extensive historical stock, we are often able to repair and test equipment that has long since been considered obsolete by the OEM.